Client Name: Kesoram

Industry: Cement

Location: India

Size: Large enterprise with a national footprint

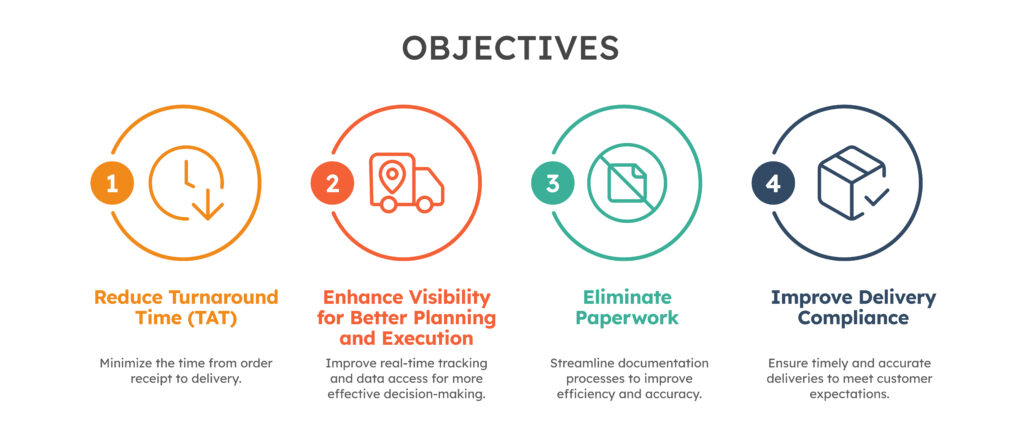

Problem Statement: Kesoram Industries faced several operational challenges, including prolonged Turnaround Time (TAT), limited visibility into the logistics process, excessive paperwork, and inconsistent delivery compliance. These issues were impacting their operational efficiency and customer satisfaction. The company aimed to address these problems by integrating advanced technologies and optimizing processes.

Challenges

- 1. High Turnaround Time (TAT): Inefficiencies in route planning, manual processes, and delays in handling impacted TAT.

- 2. Limited Visibility: Lack of real-time data and tracking made it difficult to plan and adjust operations dynamically.

- 3. Excessive Paperwork: Manual paperwork created bottlenecks, increased processing times, and led to errors.

- 4. Inconsistent Delivery Compliance: Variability in delivery times and accuracy led to customer complaints and missed service level agreements.

Solution Implementation

- 1. Reducing Turnaround Time (TAT):

- Advanced Route Optimization: Implemented an advanced route optimization system using AI to plan the most efficient delivery routes. The system considered real-time traffic data, road conditions, and delivery schedules.

- Real-Time Tracking: Deployed GPS tracking devices on all delivery vehicles to provide real-time updates and improve coordination.

- Streamlined Processes: Redesigned warehouse operations to speed up sorting, loading, and unloading. Implemented automated systems to handle high-volume processing quickly.

- 2. Enhancing Visibility for Better Planning and Execution:

- Integrated Dashboard: Introduced an integrated dashboard providing real-time visibility into the entire logistics chain, including vehicle locations, shipment statuses, and operational metrics.

- Data Analytics: Leveraged data analytics to forecast demand, optimize inventory levels, and plan resources more effectively. This helped in anticipating potential delays and making proactive adjustments.

- Collaborative Platforms: Utilized collaborative platforms to enhance communication between teams and stakeholders, improving coordination and execution.

- 3. Eliminating Paperwork:

- Digital Documentation System: Rolled out a digital documentation system to replace paper-based records. This system included electronic invoicing, digital signatures, and real-time data entry.

- Mobile Solutions: Provided mobile apps to field staff for instant data capture and updates, eliminating the need for paper forms and reducing data entry errors.

- Centralized Database: Established a centralized digital repository for all logistics-related documents, accessible by all relevant departments for seamless information flow.

- 4. Improving Delivery Compliance:

- Automated Alerts and Notifications: Set up automated alerts for delivery deadlines, compliance requirements, and real-time status updates. This ensured timely actions and adherence to service agreements.

- Performance Monitoring: Implemented performance monitoring tools to track delivery performance, compliance metrics, and customer feedback. This enabled continuous improvement based on actionable insights.

- Customer Feedback Integration: Integrated customer feedback mechanisms to capture and address issues promptly, enhancing service quality and compliance.

Conclusion

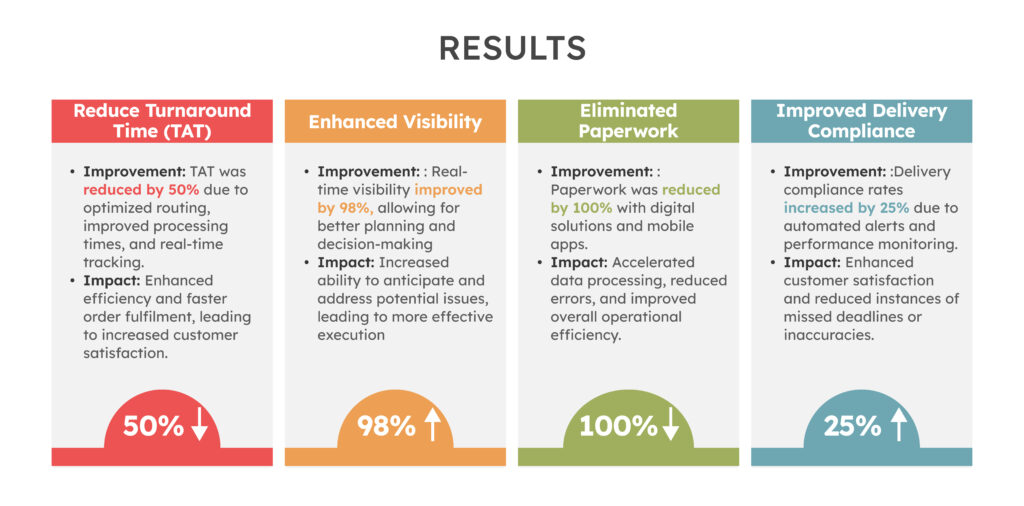

The strategic implementation of technology and process improvements at Kesoram Industries led to significant gains in efficiency and customer satisfaction. By reducing TAT, enhancing visibility, eliminating paperwork, and improving delivery compliance, the company transformed its logistics operations and established a strong competitive advantage. This case study highlights the effectiveness of integrating advanced solutions to address common challenges in the logistics industry